Difference between revisions of "Diels-Alder Reaction Experimental Design"

(→Optimum Experimental Design Problem) |

(→Optimum Experimental Design Problem) |

||

| Line 75: | Line 75: | ||

<math> | <math> | ||

\begin{array}{cll} | \begin{array}{cll} | ||

| − | \displaystyle \min_{x, G, F, Tc, n_{a1}, n_{a2}, n_{a4}, c_{kat}, \vartheta(t)} && trace(F^{-1} (t_{end})) \\[1.5ex] | + | \displaystyle \min_{x,\ G,\ F,\ Tc,\ n_{a1},\ n_{a2},\ n_{a4},\ c_{kat},\ \vartheta(t)} && trace(F^{-1} (t_{end})) \\[1.5ex] |

\mbox{s.t.} \\ | \mbox{s.t.} \\ | ||

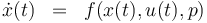

\dot{x}(t) & = & f(x(t), u(t),p), \\ | \dot{x}(t) & = & f(x(t), u(t),p), \\ | ||

Revision as of 08:53, 9 December 2015

The Diels-Alder Reaction is an organic chemical reaction. A conjugated diene and a substituted alkene react and form a substituted cyclohexene system. Stefan Körkel used this model in his PhD thesis to compute optimum experimental designs.

Model Formulation

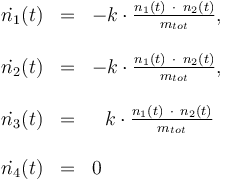

The reactionkinetics can be modelled by the following differential equation system:

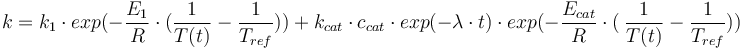

The reaction velocity constant  consists of two parts. One part reflects the non-catalytic and the other the catalytic reaction. The velocity law follows the Arrhenius relation

consists of two parts. One part reflects the non-catalytic and the other the catalytic reaction. The velocity law follows the Arrhenius relation

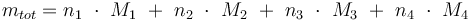

Total mass:

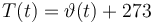

Temperature in Kelvin:

The ODE system is summarized to:

Constraints

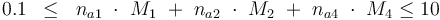

The control variables are constrained with respect to the mass of sample weights:

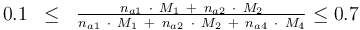

and to the mass of active ingredient content:

Optimum Experimental Design Problem

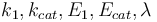

The aim is to compute an optimal experimental design  which minimizes the uncertainties of the parameters

which minimizes the uncertainties of the parameters  . So, we have to solve the following optimum experimental design problem:

. So, we have to solve the following optimum experimental design problem:

![\begin{array}{cll}

\displaystyle \min_{x,\ G,\ F,\ Tc,\ n_{a1},\ n_{a2},\ n_{a4},\ c_{kat},\ \vartheta(t)} && trace(F^{-1} (t_{end})) \\[1.5ex]

\mbox{s.t.} \\

\dot{x}(t) & = & f(x(t), u(t),p), \\

\\

h(t) & = & \frac{n_3(t) \ \cdot \ M_3}{m_{tot}} \ \cdot \ 100 \\

\\

\dot{G}(t) & = & f_x(x(t),u(t),p)G(t) \ + \ f_p(x(t),u(t),p) \\

\\

\dot{F}(t) & = & w(t) (h_x(x(t),u(t),p)G(t))^T (h_x(x(t),u(t),p)G(t)) \\

\\

0.1 & \le & n_{a1} \ \cdot \ M_1 \ + \ n_{a2} \ \cdot \ M_2 \ + \ n_{a4} \ \cdot \ M_4 \\

\\

10 & \ge & n_{a1} \ \cdot \ M_1 \ + \ n_{a2} \ \cdot \ M_2 \ + \ n_{a4} \ \cdot \ M_4 \\

\\

0.1 & \le & \frac{ n_{a1} \ \cdot \ M_1 \ + \ n_{a2} \ \cdot \ M_2 }{ n_{a1} \ \cdot \ M_1 \ + \ n_{a2} \ \cdot \ M_2 \ + \ n_{a4} \ \cdot \ M_4 } \\

\\

0.7 & \ge & \frac{ n_{a1} \ \cdot \ M_1 \ + \ n_{a2} \ \cdot \ M_2 }{ n_{a1} \ \cdot \ M_1 \ + \ n_{a2} \ \cdot \ M_2 \ + \ n_{a4} \ \cdot \ M_4 } \\

\\

T(t) & = & \vartheta_{lo} + 273, \quad \forall \, t \in [t_0,2] \\

\\

T(t) & = & \vartheta_{lo} + \frac{t-2}{6} ( \vartheta_{up} - \vartheta_{lo} ) + 273 , \quad \forall \, t \in [2,8] \\

\\

T(t) & = & \vartheta_{up} + 273, \quad \forall \, t \in [8,t_{end}] \\

\\

x & \in & \mathcal{X},\,u \in \mathcal{U},\, p \in P.

\end{array}](https://mintoc.de/images/math/8/0/9/80963931f2729762395bfb681dd3178a.png)

| Name | Symbol | Initial value ( ) )

|

| Molar number 1 |

|

|

| Molar number 2 |

|

|

| Molar number 3 |

|

|

| Solvent |

|

|

| Name | Symbol | Value |

| Molar Mass |

|

0.1362 |

| Molar Mass |

|

0.09806 |

| Molar Mass |

|

0.23426 |

| Molar Mass |

|

0.236 |

| Universal gas constant |

|

8.314 |

| Reference temperature |

|

293 |

| St.dev of measurement error |

|

1 |

Remember, in an optimum experimental design problem the parameters of the model are fixed. But, we minimize the parameter's uncertainties by optimizing over the control variables and functions.

| Name | Symbol | Value |

| Steric factor |

|

|

| Steric factor |

|

|

| Activation energie |

|

|

| Activation energie |

|

|

| Catalyst deactivation coefficient |

|

|

with

| Name | Symbol | Interval |

| Initial molar number 1 |

|

[0.4,9.0] |

| Initial molar number 2 |

|

[0.4,9.0] |

| Initial molar number 4 |

|

[0.4,9.0] |

| Concentration of the catalyst |

|

[0.0,6.0] |

| Name | Symbol | Time interval | Value interval | Initial value |

| Initial molar number 1 |

|

[math>\t_{0}</math>,2] | [20.0,100.0] | 20.0 |

| Initial molar number 1 |

|

[2,8] | [20.0,100.0] | 20.0 |

| Initial molar number 1 |

|

[8,math>\t_{end}</math>] | [20.0,100.0] | 20.0 |

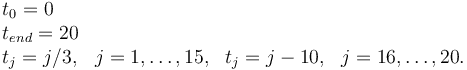

Measurement grid

References

R. T. Morrison and R.N. Boyd. Organic Chemistry. Allyn and Bacon, Inc., 4th edition, 1983 S. Körkel. Numerische Methoden für Optimale Versuchsplanungsprobleme bei nichtlinearen DAE-Modellen.PhD thesis, Universität Heidelberg, Heidelber,2002