Difference between revisions of "Bioreactor"

FelixMueller (Talk | contribs) |

FelixMueller (Talk | contribs) |

||

| (33 intermediate revisions by the same user not shown) | |||

| Line 3: | Line 3: | ||

|nx = 3 | |nx = 3 | ||

|nu = 1 | |nu = 1 | ||

| − | |nc = | + | |nc = 2 |

|nre = 3 | |nre = 3 | ||

}} | }} | ||

| Line 15: | Line 15: | ||

Originally the problem seems to be motivated by: | Originally the problem seems to be motivated by: | ||

| + | <bib id="Versyck1999" /> | ||

VERSYCK, KARINA J., and JAN F. VAN IMPE. | VERSYCK, KARINA J., and JAN F. VAN IMPE. | ||

| Line 99: | Line 100: | ||

<p> | <p> | ||

<math> | <math> | ||

| − | \begin{array}{ | + | \begin{array}{clcl} |

| − | \displaystyle \min_{x,S_f} & J(x | + | \displaystyle \min_{x,S_f} & J(x,S_f)\\[1.5ex] |

| − | \mbox{s.t.} & \dot{x} | + | \mbox{s.t.} |

| − | & x(0) = (6.5,12,22)^T \\ | + | & \dot{x} & = & f(x,S_f)\\ |

| − | & | + | & x(0) & = & (6.5,12,22)^T \\ |

| − | S_f \in [28.7,40]. | + | & S_f & \in &[28.7,40]. |

\end{array} | \end{array} | ||

</math> | </math> | ||

| Line 131: | Line 132: | ||

<!--List of all categories this page is part of. List characterization of solution behavior, model properties, ore presence of implementation details (e.g., AMPL for AMPL model) here --> | <!--List of all categories this page is part of. List characterization of solution behavior, model properties, ore presence of implementation details (e.g., AMPL for AMPL model) here --> | ||

| − | [[Category:MIOCP]] [[Category: | + | [[Category:MIOCP]] [[Category: ODE model]] [[Category:Chemical engineering]] |

| + | [[Category:Bang bang]] | ||

Latest revision as of 09:27, 27 July 2016

| Bioreactor | |

|---|---|

| State dimension: | 1 |

| Differential states: | 3 |

| Continuous control functions: | 1 |

| Path constraints: | 2 |

| Interior point equalities: | 3 |

The bioreactor problem describes an substrate that is converted to a product by the biomass in the reactor. It has three states and a control that is describing the feed concentration of the substrate. The problem is taken from the examples folder of the ACADO toolkit described in: [Houska2011a]The entry doesn't exist yet.

Houska, Boris, Hans Joachim Ferreau, and Moritz Diehl. "ACADO toolkit—An open‐source framework for automatic control and dynamic optimization." Optimal Control Applications and Methods 32.3 (2011): 298-312.

Originally the problem seems to be motivated by: [Versyck1999]The entry doesn't exist yet.

VERSYCK, KARINA J., and JAN F. VAN IMPE. "Feed rate optimization for fed-batch bioreactors: From optimal process performance to optimal parameter estimation." Chemical Engineering Communications 172.1 (1999): 107-124.

Contents

Model Formulation

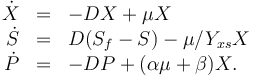

The dynamic model is an ODE model:

The right-hand side of these equations will be summed up in  .

.

The three states describe the concentration of the biomass ( ), the substrate (

), the substrate ( ), and the product (

), and the product ( ) in the reactor. In steady state the feed and outlet are equal and dilute all three concentrations with a ratio

) in the reactor. In steady state the feed and outlet are equal and dilute all three concentrations with a ratio  . The biomass grows with a rate

. The biomass grows with a rate

, while it eats up the substrate with the rate

, while it eats up the substrate with the rate  and produces product at a rate

and produces product at a rate  . The rate

. The rate  is given by:

is given by:

The fixed parameters (constants) of the model are as follows.

| Name | Symbol | Value | Unit |

| Dilution |

|

0.15 | [-] |

| Rate coefficient |

|

22 | [-] |

| Rate coefficient |

|

1.2 | [-] |

| Rate coefficient |

|

50 | [-] |

| Substrate to Biomass rate |

|

0.4 | [-] |

| Linear slope |

|

2.2 | [-] |

| Linear intercept |

|

0.2 | [-] |

| Maximal growth rate |

|

0.48 | [-] |

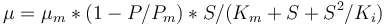

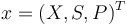

Mathematical formulation

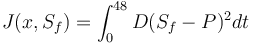

Writing shortly for the states in vector notation  the OCP reads:

the OCP reads:

![\begin{array}{clcl}

\displaystyle \min_{x,S_f} & J(x,S_f)\\[1.5ex]

\mbox{s.t.}

& \dot{x} & = & f(x,S_f)\\

& x(0) & = & (6.5,12,22)^T \\

& S_f & \in &[28.7,40].

\end{array}](https://mintoc.de/images/math/8/8/e/88e448fa43ddbb22c56b967ef453bc16.png)

Objective

Reference Solution

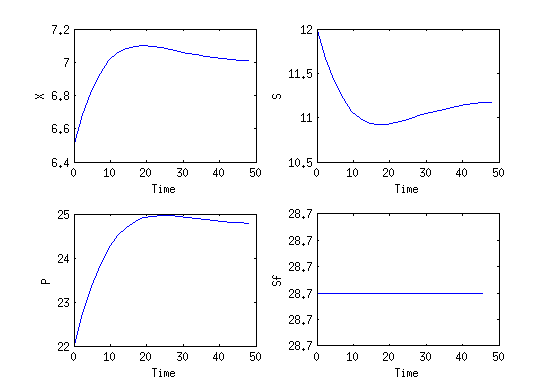

Here we present the reference solution of the reimplemented example in the ACADO code generation with matlab. The source code is given in the next section.

- Reference solution

Source Code

Model descriptions are available in