Difference between revisions of "Batch reactor"

FelixMueller (Talk | contribs) (→Mathematical formulation) |

(<math> </math> rendering appears to be broken) |

||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 3: | Line 3: | ||

|nx = 2 | |nx = 2 | ||

|nu = 1 | |nu = 1 | ||

| + | |nc = 2 | ||

|nre = 2 | |nre = 2 | ||

}} | }} | ||

| Line 39: | Line 40: | ||

This solution was computed using JuMP with a collocation method and 300 discretization points. The differential equations were solved using the explicit Euler Method. The source code can be found at [[Batch reactor (JuMP)]]. | This solution was computed using JuMP with a collocation method and 300 discretization points. The differential equations were solved using the explicit Euler Method. The source code can be found at [[Batch reactor (JuMP)]]. | ||

| − | The optimal objective value of the problem is | + | The optimal objective value of the problem is x2(tf) = 0.611715. |

<gallery caption="Reference solution plots" widths="180px" heights="140px" perrow="2"> | <gallery caption="Reference solution plots" widths="180px" heights="140px" perrow="2"> | ||

| Line 49: | Line 50: | ||

Model descriptions are available in | Model descriptions are available in | ||

| + | * [[:Category:Gekko | GEKKO Python code]] at [[Batch reactor (GEKKO)]] | ||

* [[:Category: Julia/JuMP | JuMP code]] at [[Batch reactor (JuMP)]] | * [[:Category: Julia/JuMP | JuMP code]] at [[Batch reactor (JuMP)]] | ||

| Line 58: | Line 60: | ||

[[Category:ODE model]] | [[Category:ODE model]] | ||

[[Category:Chemical engineering]] | [[Category:Chemical engineering]] | ||

| − | |||

Latest revision as of 14:42, 11 April 2019

| Batch reactor | |

|---|---|

| State dimension: | 1 |

| Differential states: | 2 |

| Continuous control functions: | 1 |

| Path constraints: | 2 |

| Interior point equalities: | 2 |

This batch reactor problem describes the consecutive reaction of some substance A via substance B into a desired product C.

The system is interacted with via the control function  which stands for the temperature.

The goal is to produce as much of substance B (which can then be converted into product C) as possible within the time limit.

which stands for the temperature.

The goal is to produce as much of substance B (which can then be converted into product C) as possible within the time limit.

Mathematical formulation

The optimal control problem is given by

![\begin{array}{llcl}

\displaystyle \max_{x, u} & x_2(t_f) \\[1.5ex]

\mbox{s.t.} & \dot{x}_1 & = & -k_1 x_1^2.\\

& \dot{x}_2 & = & k_1 x_1^2 - k_2 x_2,\\

& k_1 & = & 4000 \; e^{(-2500/T(t))}, \\

& k_2 & = & 620000 \; e^{(-5000/T(t))}, \\[1.5ex]

& x(0) &=& (1, 0)^T, \\

& T(t) &\in& [298, 398].

\end{array}](https://mintoc.de/images/math/9/f/7/9f71534dc1a851a90b41b50d9ab369a9.png)

and

and  represent the concentrations of A and B at timepoint

represent the concentrations of A and B at timepoint  respectively. The control function

respectively. The control function  represents the temperature.

represents the temperature.

Parameters

The starting time and end time are given by ![[t_0, t_f] = [0, 1]](https://mintoc.de/images/math/9/0/d/90d354576ba03d7a9fb1d63ba2ecc7cc.png) .

.

Reference Solutions

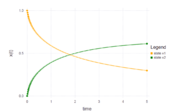

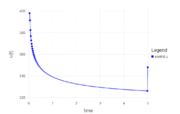

This solution was computed using JuMP with a collocation method and 300 discretization points. The differential equations were solved using the explicit Euler Method. The source code can be found at Batch reactor (JuMP).

The optimal objective value of the problem is x2(tf) = 0.611715.

- Reference solution plots

Source Code

Model descriptions are available in

References

The problem can be found in the Tomlab PROPT guide or in the Dynopt guide.

.

.