Difference between revisions of "Direct Current Transmission Heating Problem"

m (MirkoHahn moved page Direct Current Transfer Heating Problem to Direct Current Transmission Heating Problem: "Transmission" is less ambiguous and more clearly relates to "heating".) |

|||

| Line 1: | Line 1: | ||

{{Dimensions | {{Dimensions | ||

| − | |nd = | + | |nd = <math>|A|</math> |

| − | |nx = | + | |nx = <math>2 |A| + |P|</math> |

| − | |nw = | + | |nw = 0 |

|nre = 3 | |nre = 3 | ||

}} | }} | ||

| − | The '''direct current | + | The '''direct current transmission heating problem''' models a simplified flow of direct electrical current within an electrical network with defined producers and consumers of electrical power. The model includes heating and cooling that occurs in electrical conductors due to specific resistance and heat exchange with the surrounding air. An optimal strategy for regulating the power production of individual producers as well as voltages and currents on specific conductors with the goal of minimizing the net power loss due to heating on all power lines over a fixed time horizon while fully supplying all consumers. |

The model is largely assembled from well-known basic descriptions of phenomena easily accessible to the audience of high-school level physics courses. Mainly, these are [https://en.wikipedia.org/wiki/Ohm's_law Ohm's law], [https://en.wikipedia.org/wiki/Electrical_resistivity_and_conductivity electrical resistivity], [https://en.wikipedia.org/wiki/Joule_heating Joule heating] and [https://en.wikipedia.org/wiki/Thermal_conductivity thermal conductivity]. Note that changes of resistivity with respect to conductor temperature are taken into account. | The model is largely assembled from well-known basic descriptions of phenomena easily accessible to the audience of high-school level physics courses. Mainly, these are [https://en.wikipedia.org/wiki/Ohm's_law Ohm's law], [https://en.wikipedia.org/wiki/Electrical_resistivity_and_conductivity electrical resistivity], [https://en.wikipedia.org/wiki/Joule_heating Joule heating] and [https://en.wikipedia.org/wiki/Thermal_conductivity thermal conductivity]. Note that changes of resistivity with respect to conductor temperature are taken into account. | ||

| Line 44: | Line 44: | ||

</p> | </p> | ||

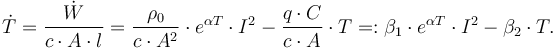

| − | For the examples in this article, we will assume the conductor to be solid copper surrounded by a layer of [https://en.wikipedia.org/wiki/Cross-linked_polyethylene cross-linked polyethylene] with a thermal conductivity of approximately <math>0.51 W / (m \cdot | + | For the examples in this article, we will assume the conductor to be solid copper surrounded by a layer of [https://en.wikipedia.org/wiki/Cross-linked_polyethylene cross-linked polyethylene (PEX)] with a thermal conductivity of approximately <math>0.51 \; W / (m \cdot K)</math>. |

== Mathematical formulation == | == Mathematical formulation == | ||

| Line 55: | Line 55: | ||

<math> | <math> | ||

\begin{array}{llcll} | \begin{array}{llcll} | ||

| − | \displaystyle \min_{T, I, u} & \int_{t_0}^{t_f} \sum_{a \in A} | + | \displaystyle \min_{T, I, u} & \int_{t_0}^{t_f} \sum_{a \in A} P_{1,a}(t) \,\mathrm{d} t \\[1.5ex] |

\mbox{s.t.} & \dot{T}_a(t) & = & \beta_{1,a} \cdot e^{\alpha_a T_a(t)} \cdot I_a(t)^2 - \beta_{2,a} \cdot T_a(t) \qquad & \forall t \in [t_0, t_f], a \in A, \\ | \mbox{s.t.} & \dot{T}_a(t) & = & \beta_{1,a} \cdot e^{\alpha_a T_a(t)} \cdot I_a(t)^2 - \beta_{2,a} \cdot T_a(t) \qquad & \forall t \in [t_0, t_f], a \in A, \\ | ||

& d_v & = & \sum_{a \in \delta^{in}(v)} (U_a \cdot I_{a}(t) - P_1^a(t)) - \sum_{a \in \delta^{out}(v)} (U_a \cdot I_a(t)) \qquad & \forall t \in [t_0, t_f], v \in V \setminus P, \\ | & d_v & = & \sum_{a \in \delta^{in}(v)} (U_a \cdot I_{a}(t) - P_1^a(t)) - \sum_{a \in \delta^{out}(v)} (U_a \cdot I_a(t)) \qquad & \forall t \in [t_0, t_f], v \in V \setminus P, \\ | ||

| Line 67: | Line 67: | ||

</p> | </p> | ||

| − | + | The differential state <math>T_a</math> describes the temperature of power line <math>a</math> while the controls <math>I_a</math> and <math>u_v</math> represent the current in a power line <math>a \in A</math> and the power produced in a production node <math>v \in P</math> | |

== Parameters == | == Parameters == | ||

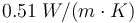

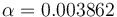

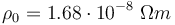

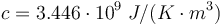

| − | + | There are multiple test scenarios. For all scenarios, we allow three types of conductors, all of which are copper (<math>\alpha = 0.003862</math>, <math>\rho_0 = 1.68 \cdot 10^{-8} \; \Omega m</math>, <math>c = 3.446 \cdot 10^9 \; J / (K \cdot m^3)</math>) cylinders surrounded by an insulating layer of PEX: | |

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Type | ||

| + | ! Voltage | ||

| + | ! Conductor diameter | ||

| + | ! Insulator thickness | ||

| + | ! <math>A</math> | ||

| + | ! <math>C</math> | ||

| + | ! <math>q</math> | ||

| + | |- | ||

| + | | A | ||

| + | | <math>330 \;kV</math> | ||

| + | | <math>7 \;cm</math> | ||

| + | | <math>2 \;cm</math> | ||

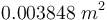

| + | | <math>0.003848 \;m^2</math> | ||

| + | | <math>0.2199 \;m</math> | ||

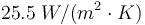

| + | | <math>25.5 \;W / (m^2 \cdot K)</math> | ||

| + | |- | ||

| + | | B | ||

| + | | <math>220 \;kV</math> | ||

| + | | <math>5 \;cm</math> | ||

| + | | <math>1.5 \;cm</math> | ||

| + | | <math>0.001963 \;m^2</math> | ||

| + | | <math>0.1571 \;m</math> | ||

| + | | <math>34 \;W / (m^2 \cdot K)</math> | ||

| + | |- | ||

| + | | C | ||

| + | | <math>110 \;kV</math> | ||

| + | | <math>3 \;cm</math> | ||

| + | | <math>0.75 \;cm</math> | ||

| + | | <math>0.0007069 \;m^2</math> | ||

| + | | <math>0.09425 \;m</math> | ||

| + | | <math>68 \;W / (m^2 \cdot K)</math> | ||

| + | |} | ||

| + | PEX looses structural integrity at operating temperatures roughly in excess of <math>120^{\circ} C</math> which means that <math>T_{max,a} = 100</math> for all three types of power lines. | ||

| − | <math> | + | === Delayed heating === |

| − | \ | + | In this scenario, we consider a simple network consisting of two producers producing <math>1 \;MW</math> each and a single consumer with a demand of <math>1.25 \;MW</math>. Both producers have direct power links of type C and length <math>1 \;km</math> to the consumer. The time horizon is defined by <math>(t_0, t_f) = (0, 300)</math>. A JSON description of the network can be found under [[Direct Current Transmission Heating Problem: Delayed heating (Network)]]. |

| − | + | ||

| − | ( | + | |

| − | + | ||

| − | </math> | + | |

== Reference Solutions == | == Reference Solutions == | ||

| − | + | TODO | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| Line 98: | Line 120: | ||

Model descriptions are available in | Model descriptions are available in | ||

| − | + | * [[:Category: Casadi | Casadi code]] at [[Direct Current Transmission Heating Problem (Casadi)]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | * [[:Category: Casadi | Casadi code]] at [[ | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

Revision as of 15:54, 8 December 2015

| Direct Current Transmission Heating Problem | |

|---|---|

| State dimension: |

|

| Differential states: |

|

| Discrete control functions: | 0 |

| Interior point equalities: | 3 |

The direct current transmission heating problem models a simplified flow of direct electrical current within an electrical network with defined producers and consumers of electrical power. The model includes heating and cooling that occurs in electrical conductors due to specific resistance and heat exchange with the surrounding air. An optimal strategy for regulating the power production of individual producers as well as voltages and currents on specific conductors with the goal of minimizing the net power loss due to heating on all power lines over a fixed time horizon while fully supplying all consumers.

The model is largely assembled from well-known basic descriptions of phenomena easily accessible to the audience of high-school level physics courses. Mainly, these are Ohm's law, electrical resistivity, Joule heating and thermal conductivity. Note that changes of resistivity with respect to conductor temperature are taken into account.

Contents

Physical background

The aim of the controller in this model is to provide all consumers with their required amount of electric power. Electric power is given by the product of voltage and current  . The electric power is brought to the consumers from producers via a network of power lines. Producers are assumed to have the capability of accurately regulating their power output within a certain range. Power lines are assumed to be solid blocks of an electrically conductive material surrounded by a layer of insulating material. Their cross-section is assumed to be constant along the entire length of the power line. Since both heating and power loss increase with current but not with voltage, it is always preferable to transfer direct current at the highest possible voltage which is allowed by the design of the power line. Therefore, only the electrical current is considered as a control.

. The electric power is brought to the consumers from producers via a network of power lines. Producers are assumed to have the capability of accurately regulating their power output within a certain range. Power lines are assumed to be solid blocks of an electrically conductive material surrounded by a layer of insulating material. Their cross-section is assumed to be constant along the entire length of the power line. Since both heating and power loss increase with current but not with voltage, it is always preferable to transfer direct current at the highest possible voltage which is allowed by the design of the power line. Therefore, only the electrical current is considered as a control.

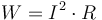

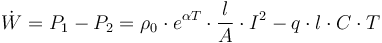

The power loss in a power line is given by  where

where  is the resistance of the power line which is derived from the resistivity of the conductor using the formula

is the resistance of the power line which is derived from the resistivity of the conductor using the formula

where  is the resistivity of the conductor,

is the resistivity of the conductor,  is the length of the conductor and

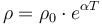

is the length of the conductor and  is the the cross-sectional area of the conducting material within the power line. Resistivity is assumed to vary exponentially with the temperature of the conducting material, meaning that

is the the cross-sectional area of the conducting material within the power line. Resistivity is assumed to vary exponentially with the temperature of the conducting material, meaning that  where

where  is the resistivity of the conducting material at room temperature (which is defined as

is the resistivity of the conducting material at room temperature (which is defined as  ) and

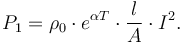

) and  is a material-specific dimensionless constant. This causes a steady power loss of

is a material-specific dimensionless constant. This causes a steady power loss of

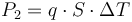

The lost energy is transformed into heat which raises the temperature of the conductor. As the conductor is now hotter than the air surrounding its layer of insulating material, heat is steadily lost at a rate determined by the temperature difference, the conductors surface area and the insulating material's heat conductivity. The heat loss is given by

where  is the ratio between the isolating material's thermal conductivity and its thickness,

is the ratio between the isolating material's thermal conductivity and its thickness,  is the surface area of the power line and

is the surface area of the power line and  is the difference between the conductor's temperature and the surrounding air's temperature (which we will assume to be the same as room temperature, i.e.

is the difference between the conductor's temperature and the surrounding air's temperature (which we will assume to be the same as room temperature, i.e.  ). In summary, the rate at which the heat stored in a power line changes is given by

). In summary, the rate at which the heat stored in a power line changes is given by

where  is the circumference of the cross-section of the power line. Assuming constant density, we can use the conducting materials volume-specific heat capacity which we will refer to as

is the circumference of the cross-section of the power line. Assuming constant density, we can use the conducting materials volume-specific heat capacity which we will refer to as  , we can calculate the change in temperature from the change in heat:

, we can calculate the change in temperature from the change in heat:

For the examples in this article, we will assume the conductor to be solid copper surrounded by a layer of cross-linked polyethylene (PEX) with a thermal conductivity of approximately  .

.

Mathematical formulation

Let  a directed graph with vertex set

a directed graph with vertex set  and arc set

and arc set  . Let

. Let  be disjoint subsets of the vertex set.

be disjoint subsets of the vertex set.  serves as the set of producer nodes while

serves as the set of producer nodes while  serves as the set of consumers. For

serves as the set of consumers. For  let

let  denote the power demand for

denote the power demand for  . For

. For  , let

, let  .

.

The resulting optimal control problem is given by

![\begin{array}{llcll}

\displaystyle \min_{T, I, u} & \int_{t_0}^{t_f} \sum_{a \in A} P_{1,a}(t) \,\mathrm{d} t \\[1.5ex]

\mbox{s.t.} & \dot{T}_a(t) & = & \beta_{1,a} \cdot e^{\alpha_a T_a(t)} \cdot I_a(t)^2 - \beta_{2,a} \cdot T_a(t) \qquad & \forall t \in [t_0, t_f], a \in A, \\

& d_v & = & \sum_{a \in \delta^{in}(v)} (U_a \cdot I_{a}(t) - P_1^a(t)) - \sum_{a \in \delta^{out}(v)} (U_a \cdot I_a(t)) \qquad & \forall t \in [t_0, t_f], v \in V \setminus P, \\

& u_v(t) & = & \sum_{a \in \delta^{in}(v)} (U_a \cdot I_{a}(t) - P_1^a(t)) - \sum_{a \in \delta^{out}(v)} (U_a \cdot I_a(t)) \qquad & \forall t \in [t_0, t_f], v \in P, \\[1.5ex]

& T_a(t_0) &=& 0.0 \qquad & \forall a \in A, \\

& I_a(t) &\in& [0, I_{max, a}] \qquad & \forall a \in A, t \in [t_0, t_f], \\

& T_a(t) &\in& [0, T_{max, a}] \qquad & \forall a \in A, t \in [t_0, t_f], \\

& u_v(t) &\in& [0, u_{max, v}] \qquad & \forall v \in P, t \in [t_0, t_f].

\end{array}](https://mintoc.de/images/math/7/5/d/75d23bc23c225a0ddb8a3231fa7daa5d.png)

The differential state  describes the temperature of power line

describes the temperature of power line  while the controls

while the controls  and

and  represent the current in a power line

represent the current in a power line  and the power produced in a production node

and the power produced in a production node

Parameters

There are multiple test scenarios. For all scenarios, we allow three types of conductors, all of which are copper ( ,

,  ,

,  ) cylinders surrounded by an insulating layer of PEX:

) cylinders surrounded by an insulating layer of PEX:

| Type | Voltage | Conductor diameter | Insulator thickness |

|

|

|

|---|---|---|---|---|---|---|

| A |

|

|

|

|

|

|

| B |

|

|

|

|

|

|

| C |

|

|

|

|

|

|

PEX looses structural integrity at operating temperatures roughly in excess of  which means that

which means that  for all three types of power lines.

for all three types of power lines.

Delayed heating

In this scenario, we consider a simple network consisting of two producers producing  each and a single consumer with a demand of

each and a single consumer with a demand of  . Both producers have direct power links of type C and length

. Both producers have direct power links of type C and length  to the consumer. The time horizon is defined by

to the consumer. The time horizon is defined by  . A JSON description of the network can be found under Direct Current Transmission Heating Problem: Delayed heating (Network).

. A JSON description of the network can be found under Direct Current Transmission Heating Problem: Delayed heating (Network).

Reference Solutions

TODO

Source Code

Model descriptions are available in