Difference between revisions of "Bioreactor"

m (SebastianSager moved page Bioreactor example to Bioreactor without leaving a redirect: example not needed) |

TobiasWeber (Talk | contribs) |

||

| Line 1: | Line 1: | ||

| − | The bioreactor | + | The bioreactor problem describes an substrate that is converted to a product by the biomass in the reactor. It has three states and a control that is describing the feed concentration of the substrate. The problem is taken from the examples folder of the ACADO toolkit described in: |

Houska, Boris, Hans Joachim Ferreau, and Moritz Diehl. "ACADO toolkit—An open‐source framework for automatic control and dynamic optimization." | Houska, Boris, Hans Joachim Ferreau, and Moritz Diehl. "ACADO toolkit—An open‐source framework for automatic control and dynamic optimization." | ||

Revision as of 10:19, 16 December 2015

The bioreactor problem describes an substrate that is converted to a product by the biomass in the reactor. It has three states and a control that is describing the feed concentration of the substrate. The problem is taken from the examples folder of the ACADO toolkit described in:

Houska, Boris, Hans Joachim Ferreau, and Moritz Diehl. "ACADO toolkit—An open‐source framework for automatic control and dynamic optimization." Optimal Control Applications and Methods 32.3 (2011): 298-312.

Originally the problem seems to be motivated by:

VERSYCK, KARINA J., and JAN F. VAN IMPE. "Feed rate optimization for fed-batch bioreactors: From optimal process performance to optimal parameter estimation." Chemical Engineering Communications 172.1 (1999): 107-124.

Contents

[hide]Model Formulation

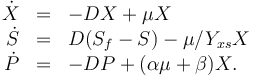

The dynamic model is an ODE model:

The three states describe the concentration of the biomass ( ), the substrate (

), the substrate ( ), and the product (

), and the product ( ) in the reactor. In steady state the feed and outlet are equal and dilute all three concentrations with a ratio

) in the reactor. In steady state the feed and outlet are equal and dilute all three concentrations with a ratio  . The biomass grows with a rate

. The biomass grows with a rate

, while it eats up the substrate with the rate

, while it eats up the substrate with the rate  and produces product at a rate

and produces product at a rate  . The rate

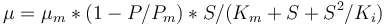

. The rate  is given by:

is given by:

The fixed parameters (constants) of the model are as follows.

| Name | Symbol | Value | Unit |

| Dilution |

|

0.15 | [-] |

| Rate coefficient |

|

22 | [-] |

| Rate coefficient |

|

1.2 | [-] |

| Rate coefficient |

|

50 | [-] |

| Substrate to Biomass rate |

|

0.4 | [-] |

| Linear slope |

|

2.2 | [-] |

| Linear intercept |

|

0.2 | [-] |

| Maximal growth rate |

|

0.48 | [-] |

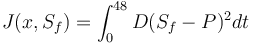

Optimal Control Problem

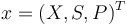

Writing shortly for the states in vector notation  the OCP reads:

the OCP reads:

![\begin{array}{cl}

\displaystyle \min_{x,S_f} & J(x,S_f)\\[1.5ex]

\mbox{s.t.} & \dot{x} = f(x,S_f), \forall \, t \in [0,48]\\

& x(0) = (6.5,12,22)^T \\

& x \in \R^3,\,S_f \in [28.7,40].

\end{array}](https://mintoc.de/images/math/8/f/a/8faa15c9069ea63b2a4359012e47ea77.png)

Objective

Reference Solution

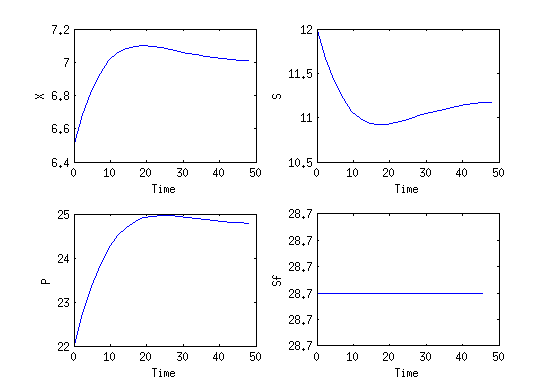

Here we present the reference solution of the reimplemented example in the ACADO code generation with matlab. The source code is given in the next section.

- Reference solution

Source Code

This is the implementation of the ACADO bioreactor example with the matlab interface and the code generation of ACADO.

% implements the bioreactor example of ACADO for the matlab interface and

% the code generation

clc;

clear all;

close all;

Ts = 0.1;

EXPORT = 1;

%% Variables

DifferentialState X S P;

Control Sf;

n_XD = length(diffStates);

n_U = length(controls);

%% Constants

D = 0.15;

Ki = 22.0;

Km = 1.2 ;

Pm = 50.0;

Yxs = 0.4 ;

alpha = 2.2 ;

beta = 0.2 ;

mum = 0.48;

Sfmin = 28.7;

Sfmax = 40.0;

t_start = 0.0;

t_end = 48.0;

N = 20;

%% Differential Equation

mu = mum*(1-P/Pm)*S/(Km+S+S^2/Ki);

f = dot([X;S;P]) == [-D*X+mu*X;...

D*(Sf-S)-(mu/Yxs)*X;...

-D*P+(alpha*mu+beta)*X];

% output

h = P-Sf;

hN = P;

%% MPCexport

acadoSet('problemname', 'mpc');

ocp = acado.OCP( t_start, t_end, N );

W_mat = D;

WN_mat = D;

W = acado.BMatrix(W_mat);

WN = acado.BMatrix(WN_mat);

ocp.minimizeLSQ( W, h );

ocp.minimizeLSQEndTerm( WN, hN );

ocp.subjectTo( Sfmin <= Sf <= Sfmax );

ocp.setModel(f);

mpc = acado.OCPexport( ocp );

mpc.set( 'HESSIAN_APPROXIMATION', 'GAUSS_NEWTON' );

mpc.set( 'DISCRETIZATION_TYPE', 'MULTIPLE_SHOOTING' );

mpc.set( 'SPARSE_QP_SOLUTION', 'FULL_CONDENSING_N2');

mpc.set( 'INTEGRATOR_TYPE', 'INT_IRK_GL4' );

mpc.set( 'NUM_INTEGRATOR_STEPS', 10*N );

mpc.set( 'QP_SOLVER', 'QP_QPOASES' );

mpc.set( 'HOTSTART_QP', 'NO' );

mpc.set( 'LEVENBERG_MARQUARDT', 1e-10 );

if EXPORT

mpc.exportCode( 'export_MPC' );

copyfile('../../../../../../external_packages/qpoases', 'export_MPC/qpoases')

cd export_MPC

make_acado_solver('../acado_MPCstep')

cd ..

end

%% CONSTANTS FOR OPTIMIZATION

X0 = [6.5 12.0 22.0];

input.x0=X0';

Xref = [0 0 0];

input.x = repmat(Xref,N+1,1);

Xref = repmat(Xref,N,1);

input.od = [];

Uref = zeros(N,n_U);

input.u = Uref;

input.y = Sfmin*ones(N,1);

input.yN = Sfmin;

input.W = 1;

input.WN = 1;

%% SOLVER LOOP (SQP - Gauss newton)

display('------------------------------------------------------------------')

display(' SOLVER Loop' )

display('------------------------------------------------------------------')

for i=1:20

tic

% Solve NMPC OCP

output = acado_MPCstep(input);

input.x=output.x;

input.u=output.u;

disp([' (RTI step: ' num2str(output.info.cpuTime*1e6) ' µs)'])

end

%% PLOT RESULTS

% States

figure(1)

plot([t_start:t_end/N:t_end],output.x)

ylabel('States')

xlabel('Time')

legend('X','S','P')

% Control

figure(2)

plot([t_start:t_end/N:t_end-t_end/N],output.u)

ylabel('Control (Sf)')

xlabel('Time')

% one figure for all

figure(3)

subplot(2,2,1)

plot([t_start:t_end/N:t_end],output.x(:,1))

ylabel('X')

xlabel('Time')

subplot(2,2,2)

plot([t_start:t_end/N:t_end],output.x(:,2))

ylabel('S')

xlabel('Time')

subplot(2,2,3)

plot([t_start:t_end/N:t_end],output.x(:,3))

ylabel('P')

xlabel('Time')

subplot(2,2,4)

plot([t_start:t_end/N:t_end-t_end/N],output.u)

ylabel('Sf')

xlabel('Time')