Difference between revisions of "DOW Experimental Design"

RobertLampel (Talk | contribs) (→Mathematical formulation) |

RobertLampel (Talk | contribs) (→Mathematical formulation) |

||

| Line 131: | Line 131: | ||

</math> | </math> | ||

</p> | </p> | ||

| − | Here the letters in parentheses stand for the corresponding chemical process and the quantity <math>\left[Q^+\right]=0. | + | Here the letters in parentheses stand for the corresponding chemical process and the quantity <math>\left[Q^+\right]=0.00131</math> is a constant during the reaction. |

The nine parameters form the vector | The nine parameters form the vector | ||

<p> | <p> | ||

Revision as of 14:25, 12 December 2024

| DOW Experimental Design | |

|---|---|

| State dimension: | 1 |

| Differential states: | 11 |

| Discrete control functions: | 2 |

| Path constraints: | 4 |

| Interior point equalities: | 11 |

The DOW Experimental Design problem models the OED problem for the parameter estimation problem formulated by the DOW Chemical Co. in 1981. The following formulation is taken from [1].

Contents

[hide]Chemical background

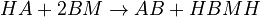

The chemical species are disguised for proprietary reasons and the desired reaction is given by  , where

, where  is the desired product. The reactions are described as follows:

is the desired product. The reactions are described as follows:

Slow Kinetic Reactions:

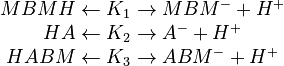

Acid-Base Reactions:

In order to devise a model to account for these reactions, it is first necessary to distinguish between the overall concentration of a species and the concentration of its neutral form. Overall concentrations are defined for three components based on neutral and ionic species

![\begin{align}

\left[HBMH\right] &= \left[ (MBMH)_N \right] + \left[ MBM^- \right] \\

\left[HA\right] &= \left[ (HA)_N \right] + \left[ A^- \right] \\

\left[HABM\right] &= \left[ (HABM)_N \right] + \left[ ABM^- \right]

\end{align}](https://mintoc.de/images/math/8/a/9/8a90809e1d9fb52552b742b87f38a098.png)

Here ![[ \ ]](https://mintoc.de/images/math/7/5/4/7541b1af090dec7db3eb1953f2b90cc1.png) denotes the concentration of the species in

denotes the concentration of the species in  .

By assuming the rapid acid-base reactions are at equilibrium, the equilibrium constants

.

By assuming the rapid acid-base reactions are at equilibrium, the equilibrium constants  can be defined as

can be defined as

![\begin{align}

K_1 &= \frac{[MBM^-][H^+]}{[(MBMH)_N]} \\

K_2 &= \frac{[A^-][H^+]}{[(HA)_N]} \\

K_3 &= \frac{[ABM^-][H^+]}{[(HABM)_N]}

\end{align}](https://mintoc.de/images/math/0/f/c/0fc9353e835b909394feb2943063cf73.png)

The anionic species may then be represented by

![\begin{align}

\left[MBM^-\right] &= \frac{K_1[MBMH]}{K_1 + [H^+]} && \quad (a) \\

\left[A^-\right] &= \frac{K_2[HA]}{K_2 + [H^+]} && \quad (b)\\

\left[ABM^-\right] &= \frac{K_3[HABM]}{K_3 + [H^+]} && \quad (c)

\end{align}](https://mintoc.de/images/math/9/e/e/9ee28304dd2ce28499942f31c87106a4.png)

Material balance equations for the three reactants in the slow kinetic reactions yield:

![\begin{align}

\frac{d[M^-]}{dt} &= -k_1 \left[ M^- \right] \left[ BM \right] + k_{-1} \left[ MBM^- \right] - k_3 \left[ M^- \right]\left[ AB \right] + k_{-1} \left[ ABM^- \right] && \quad (d)\\

\frac{d[BM]}{dt} &= -k_1 \left[ M^- \right] \left[ BM \right] + k_{-1} \left[ MBM^- \right] - k_2 \left[ A^- \right]\left[ BM \right] && \quad (e)\\

\frac{d[AB]}{dt} &= -k_3 \left[ M^- \right] \left[ AB \right] + k_{-3} \left[ ABM^- \right] && \quad (f)

\end{align}](https://mintoc.de/images/math/6/e/7/6e7496978a48089559abb74f5d4859ac.png)

From stoichiometry, rate expressions can also be written for the total species:

![\begin{align}

\frac{d[MBMH]}{dt} &= k_1 \left[ M^- \right] \left[ BM \right] + k_{-1} \left[ MBM^- \right] && \quad (g)\\

\frac{d[HA]}{dt} &= k_2 \left[ A^- \right] \left[ BM \right] && \quad (h)\\

\frac{d[HABM]}{dt} &= k_2 \left[ A^- \right] \left[ BM \right] + k_3 \left[ M^- \right] \left[ AB \right] - k_{-3} \left[ ABM^- \right] && \quad (i)

\end{align}](https://mintoc.de/images/math/6/b/8/6b8bcc6fcbbd5783e833a3373e3aa6af.png)

An electroneutrality constraint gives the hydrogen ion concentration ![\left[ H^+ \right]](https://mintoc.de/images/math/a/d/0/ad0539982a2a429c51ee7e34fc22d0d4.png) as

as

![\left[ H^+ \right] + \left[ Q^+ \right] = \left[ M^- \right] + \left[ MBM^- \right] + \left[ A^- \right] + \left[ ABM^- \right] \quad \quad (j)](https://mintoc.de/images/math/a/c/7/ac79dfa07916df16abf91a7746ab38fb.png)

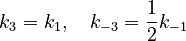

Based on similarities of reacting species, we assume

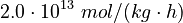

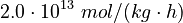

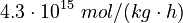

With these assumptions, the three rate constants  and

and  must be estimated. Each of these can be fitted with two adjustable model parameters, assuming an Arrhenius temperature dependence. That is

must be estimated. Each of these can be fitted with two adjustable model parameters, assuming an Arrhenius temperature dependence. That is

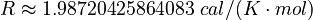

Here  is the gas constant and

is the gas constant and  is the reaction temperature in Kelvins. The parameters

is the reaction temperature in Kelvins. The parameters  , given in

, given in  , represent the pre-exponential factors and the

, represent the pre-exponential factors and the  , with unit

, with unit  , are the activation energies.

, are the activation energies.

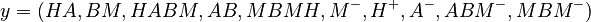

Mathematical formulation

The chemical processes  can be expressed mathematically as six differential equations and four algebraic equations:

can be expressed mathematically as six differential equations and four algebraic equations:

![\begin{align}

\dot{y}_1 &= -k_2 y_8 y_2 && \quad (1),(h) \\

\dot{y}_2 &= -k_1 y_6 y_2 + k_{-1} y_{10} - k_2 y_8 y_2 && \quad (2),(e) \\

\dot{y}_3 &= k_2 y_8 y_2 + k_1 y_6 y_4 - \frac{1}{2} k_{-1} y_9 && \quad (3),(i) \\

\dot{y}_4 &= -k_1 y_6 y_4 + \frac{1}{2} k_{-1} y_9 && \quad (4),(f) \\

\dot{y}_5 &= k_1 y_6 y_2 - k_{-1} y_{10} && \quad (5),(g) \\

\dot{y}_6 &= -k_1 (y_6 y_2 + y_6 y_4) + k_{-1} (y_{10} + \frac{1}{2} y_9) && \quad (6),(d) \\

y_7 &= -\left[ Q^+ \right] + y_6 + y_8 + y_9 + y_{10} && \quad (7),(j)\\

y_8 &= \frac{\theta_8 y_1}{\theta_8 + y_7} && \quad (8),(b)\\

y_9 &= \frac{\theta_9 y_3}{\theta_9 + y_7} && \quad (9),(c)\\

y_{10} &= \frac{\theta_7 y_5}{\theta_7 + y_7} && \quad (10),(a)

\end{align}](https://mintoc.de/images/math/c/d/8/cd8bdeab86edf9fad2f9422431b74bc0.png)

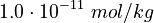

Here the letters in parentheses stand for the corresponding chemical process and the quantity ![\left[Q^+\right]=0.00131](https://mintoc.de/images/math/1/6/4/164e0f742cb3231f492ad925072f8e33.png) is a constant during the reaction.

The nine parameters form the vector

is a constant during the reaction.

The nine parameters form the vector

The predicted concentrations form the vector

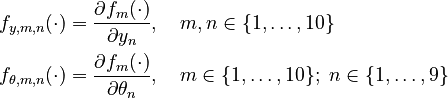

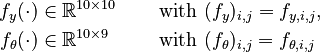

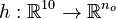

Let  denote the right hand side of equation

denote the right hand side of equation  for

for  .

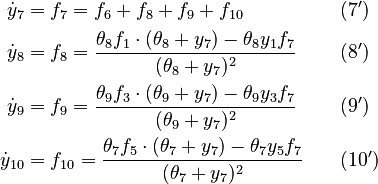

We reformulate the last four algebraic equations as differential ones:

.

We reformulate the last four algebraic equations as differential ones:

The right hand sides of  and

and  are summarized as the vector-valued function

are summarized as the vector-valued function  .

Moreover, let

.

Moreover, let

Parameters

The initial parameter estimates are:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

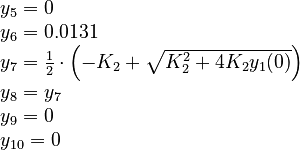

There are three datasets for different temperatures  , with corresponding starting values

, with corresponding starting values

|

|

|

|

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The initial model conditions in addition to those given in the data sets are:

Optimal Experimental Design Problem

To be specified.

We are interested in when to measure (with an upper bound  on the measuring time for each observable).

We define

on the measuring time for each observable).

We define

In this approach, we add the so-called sensitivities  . For the differential equations this means

. For the differential equations this means

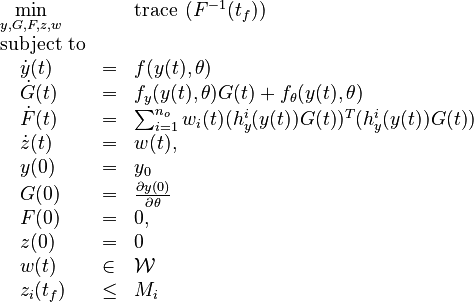

Now we formulate the OED problem as described in [2].

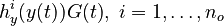

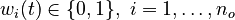

Here  is the observed function. The

evolution of the symmetric matrix

is the observed function. The

evolution of the symmetric matrix ![F: \left[0,t_f \right] \rightarrow \mathbb{R}^{9 \times 9}](https://mintoc.de/images/math/7/1/8/718334578e24248dfbe68e385a44ec30.png) is given by the weighted sum of observability Gramians

is given by the weighted sum of observability Gramians

for each observed function of states. The weights

for each observed function of states. The weights  are the (binary) sampling decisions, where

are the (binary) sampling decisions, where  denotes the decision to perform a measurement at

time

denotes the decision to perform a measurement at

time  .

.

Miscellaneous and Further Reading

To be specified.

References

[1] "Nonlinear Parameter Estimation: a Case Study Comparison" by L. T. Biegler and J. J. Damiano

[2] "Optimal Experimental Design for Universal Differential Equations" by C. Plate, C.J. Martensen and S. Sager

[3] "Parameter estimation in nonlinear systems" by W.J.H. Stortelder