Difference between revisions of "Supermarket refrigeration system"

m |

FelixMueller (Talk | contribs) |

||

| (31 intermediate revisions by 5 users not shown) | |||

| Line 2: | Line 2: | ||

|nd = 1 | |nd = 1 | ||

|nx = 9 | |nx = 9 | ||

| − | |nw = | + | |nw = 3 |

| − | | | + | |nc = 7 |

| + | |nre = 9 | ||

}} | }} | ||

| − | The '''supermarket refrigeration system problem''' is based on a model describing a refrigeration system with 2 parallel connected compressors (called a compressor rack) which only can be controlled stepwise (each single compressor can be turned on or off) and 2 open refrigerated display cases containing goods needed to be refrigerated. Each display case is connected to the refrigeration circuit through an expansion valve which also can only be closed or opened. | + | The '''supermarket refrigeration system problem''' is based on a model describing a refrigeration system with 2 parallel connected compressors (called a compressor rack) which only can be controlled stepwise (each single compressor can be turned on or off) and 2 open refrigerated display cases containing goods needed to be refrigerated. Each display case is connected to the refrigeration circuit through an expansion valve which also can only be closed or opened. This valve controls the flow of refrigerant into the evaporator, where it absorbs heat from the surrounding air. The refrigerated air then creates the well-known air-curtain at the front of the display case. |

The air temperatures surrounding the goods in each display case are modeled by one differential state each. These states have to be bounded, so that the goods are properly refrigerated. | The air temperatures surrounding the goods in each display case are modeled by one differential state each. These states have to be bounded, so that the goods are properly refrigerated. | ||

| − | The model was published by Larsen et. al. in 2007 < | + | The model was published by Larsen et. al. in 2007 <bib id="Larsen2007" />. The main goal is to control the refirgeration system energy-optimal. The problem was set up as a benchmark problem for MIOCPs. |

| − | The mathematical equations form an [[:Category:ODE | + | The mathematical equations form an [[:Category:ODE model|ODE model]]. The initial values of the differential states are not fixed but periodicity of the whole process is required. |

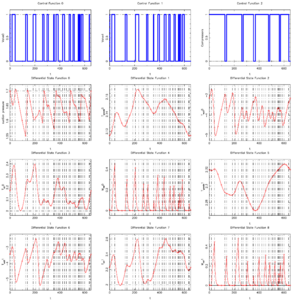

| − | The optimal integer control | + | The optimal integer control function shows [[:Category:Chattering|chattering]] behavior, making the supermarket refrigeration system problem a candidate for benchmarking of algorithms. |

== Mathematical formulation == | == Mathematical formulation == | ||

| Line 20: | Line 21: | ||

For <math>t \in [t_0, t_f]</math> almost everywhere the mixed-integer optimal control problem is given by | For <math>t \in [t_0, t_f]</math> almost everywhere the mixed-integer optimal control problem is given by | ||

| − | + | <p> | |

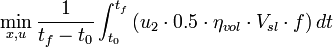

<math> | <math> | ||

| − | \min_{x,u} \frac {1}{t_f - t_0}\int_{t_0}^{t_f} \left | + | \min_{x,u} \frac {1}{t_f - t_0}\int_{t_0}^{t_f} \left( u_2 \cdot 0.5 \cdot \eta_{vol} \cdot V_{sl} \cdot f \right) dt |

</math> | </math> | ||

| + | </p> | ||

| + | |||

| + | <p> | ||

<math> | <math> | ||

\begin{array}{llcl} | \begin{array}{llcl} | ||

\displaystyle | \displaystyle | ||

| − | \mbox{s.t.} & \dot{x_0} | + | \mbox{s.t.} & |

| + | \dot{x_0} &=& \dfrac{1}{V_{suc} \cdot \frac{d\rho_{suc}}{dP_{suc}}(x_0)} \cdot \bigg[ | ||

\left(\dfrac{UA_{wall-ref, max}}{M_{ref, max} \cdot | \left(\dfrac{UA_{wall-ref, max}}{M_{ref, max} \cdot | ||

\Delta h_{lg}(x_0)}\right) \Big( x_4 \big( x_2 - T_e(x_0) \big)\\ | \Delta h_{lg}(x_0)}\right) \Big( x_4 \big( x_2 - T_e(x_0) \big)\\ | ||

| − | & && + \, x_8 \big( x_6 - T_e(x_0) \big) \Big) + \, M_{ref,const} - \eta_{vol} \cdot V_{sl} \cdot 0.5 \, | + | & && + \, x_8 \big( x_6 - T_e(x_0) \big) \Big) + \, M_{ref,const} - \eta_{vol} \cdot V_{sl} \cdot 0.5 \, u_2 \rho_{suc}(x_0) |

\bigg] \\ | \bigg] \\ | ||

| − | &\dot{x_1} | + | &\dot{x_1} &=& - \dfrac{ |

UA_{goods-air} \left( x_1 - x_3 \right) | UA_{goods-air} \left( x_1 - x_3 \right) | ||

}{ | }{ | ||

M_{goods} \cdot C_{p,goods} | M_{goods} \cdot C_{p,goods} | ||

| − | } | + | } \\ |

| − | &\dot{x_2} | + | &\dot{x_2} &=& \dfrac{ |

UA_{air-wall} \left( x_3-x_2 \right) | UA_{air-wall} \left( x_3-x_2 \right) | ||

- \dfrac{UA_{wall-ref,max}}{M_{ref,max}} | - \dfrac{UA_{wall-ref,max}}{M_{ref,max}} | ||

| Line 43: | Line 48: | ||

}{ | }{ | ||

M_{wall} \cdot C_{p,wall} | M_{wall} \cdot C_{p,wall} | ||

| − | } | + | } \\ [2.5ex] |

| − | &\dot{x_3} | + | &\dot{x_3} &=& \dfrac{ |

UA_{goods-air} \left( x_1-x_3 \right) + \dot{Q}_{airload} | UA_{goods-air} \left( x_1-x_3 \right) + \dot{Q}_{airload} | ||

- UA_{air-wall} \, (x_3-x_2) | - UA_{air-wall} \, (x_3-x_2) | ||

}{ | }{ | ||

M_{air} \cdot C_{p,air} | M_{air} \cdot C_{p,air} | ||

| − | } \\ | + | } \\ [2.5ex] |

| − | &\dot{x_4} | + | &\dot{x_4} &=& \left(\dfrac{M_{ref,max} - x_4}{\tau_{fill}} \right) u_0 |

- \left( \dfrac{UA_{wall-ref,max}}{M_{ref,max} \cdot \Delta h_{lg}(x_0)} \, | - \left( \dfrac{UA_{wall-ref,max}}{M_{ref,max} \cdot \Delta h_{lg}(x_0)} \, | ||

x_4 \big( x_2 - T_e(x_0) \big) \right) (1-u_0) | x_4 \big( x_2 - T_e(x_0) \big) \right) (1-u_0) | ||

\\ \\ | \\ \\ | ||

| − | &\dot{x_5} | + | &\dot{x_5} &=& - \dfrac{ |

UA_{goods-air} \left( x_5 - x_7 \right) | UA_{goods-air} \left( x_5 - x_7 \right) | ||

}{ | }{ | ||

M_{goods} \cdot C_{p,goods} | M_{goods} \cdot C_{p,goods} | ||

| − | } | + | } \\ |

| − | &\dot{x_6} | + | &\dot{x_6} &=& \dfrac{ |

UA_{air-wall} \left( x_7-x_6 \right) | UA_{air-wall} \left( x_7-x_6 \right) | ||

- \dfrac{UA_{wall-ref,max}}{M_{ref,max}} | - \dfrac{UA_{wall-ref,max}}{M_{ref,max}} | ||

| Line 65: | Line 70: | ||

}{ | }{ | ||

M_{wall} \cdot C_{p,wall} | M_{wall} \cdot C_{p,wall} | ||

| − | } | + | } \\ [2.5ex] |

| − | &\dot{x_7} | + | &\dot{x_7} &=& \dfrac{ |

UA_{goods-air} \left( x_5-x_7 \right) + \dot{Q}_{airload} | UA_{goods-air} \left( x_5-x_7 \right) + \dot{Q}_{airload} | ||

- UA_{air-wall} \, (x_7-x_6) | - UA_{air-wall} \, (x_7-x_6) | ||

}{ | }{ | ||

M_{air} \cdot C_{p,air} | M_{air} \cdot C_{p,air} | ||

| − | } \\ | + | } \\ [2.5ex] |

| − | &\dot{x_8} | + | &\dot{x_8} &=& \left(\dfrac{M_{ref,max} - x_8}{\tau_{fill}} \right) u_1 |

- \left( \dfrac{UA_{wall-ref,max}}{M_{ref,max} \cdot \Delta h_{lg}(x_0)} \, | - \left( \dfrac{UA_{wall-ref,max}}{M_{ref,max} \cdot \Delta h_{lg}(x_0)} \, | ||

x_8 \big( x_6 - T_e(x_0) \big) \right) (1-u_1) | x_8 \big( x_6 - T_e(x_0) \big) \right) (1-u_1) | ||

| − | \\ | + | \\ [4ex] |

| − | & 2.0 &\leq& | + | & x_3 &\geq& 2.0 \quad \forall t \in [t_0, t_f],\\ |

| − | & x_0 | + | & x_3 &\leq& 5.0 \quad \forall t \in [t_0, t_f],\\ |

| − | & x_i(t_0) &=& free \quad \forall i \in \{0,\dots 8\}, \\ | + | & x_7 &\geq& 2.0 \quad \forall t \in [t_0, t_f],\\ |

| − | & x_i(t_f) &=& x_i(t_0) \quad \forall i \in \{0,\dots 8\}, \\ | + | & x_7 &\leq& 5.0 \quad \forall t \in [t_0, t_f],\\ |

| − | & u_i(t) &\in& \{0, 1\} \quad \forall i \in \{0,\dots | + | & x_0 &\leq& 1.7 \quad \forall t \in [t_0, t_f], \\ |

| − | & t_f &\in& [ 650, 750 ]. | + | & x_i(t_0) &=& free \quad \forall i \in \{0,\dots, 8\}, \\ |

| + | & x_i(t_f) &=& x_i(t_0) \quad \forall i \in \{0,\dots, 8\}, \\ | ||

| + | & u_i(t) &\in& \{0, 1\} \quad \forall i \in \{0,\dots, 2\}, \\ | ||

| + | & t_f &\in& [ 650, 750 ]. | ||

\end{array} | \end{array} | ||

</math> | </math> | ||

| − | + | </p> | |

| Line 98: | Line 106: | ||

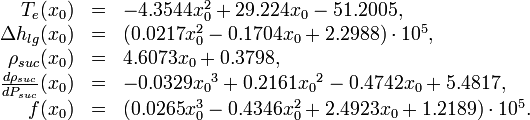

The following polynomial functions are used in the model description originating from interpolations: | The following polynomial functions are used in the model description originating from interpolations: | ||

| + | <p> | ||

<math> | <math> | ||

\begin{array}{rcl} | \begin{array}{rcl} | ||

| Line 106: | Line 115: | ||

\frac{d\rho_{suc}}{dP_{suc}}(x_0) &=& -0.0329 {x_0}^3 + 0.2161 {x_0}^2 - 0.4742 x_0 + 5.4817,\\ | \frac{d\rho_{suc}}{dP_{suc}}(x_0) &=& -0.0329 {x_0}^3 + 0.2161 {x_0}^2 - 0.4742 x_0 + 5.4817,\\ | ||

f(x_0) &=& (0.0265 x_0^3 - 0.4346 x_0^2 + 2.4923 x_0 + 1.2189) \cdot 10^5. | f(x_0) &=& (0.0265 x_0^3 - 0.4346 x_0^2 + 2.4923 x_0 + 1.2189) \cdot 10^5. | ||

| − | |||

| − | |||

| − | |||

\end{array} | \end{array} | ||

</math> | </math> | ||

| + | </p> | ||

== Parameters == | == Parameters == | ||

| Line 116: | Line 123: | ||

These fixed values are used within the model for the day scenario. A night scenario is also available, see [[#Variants|Variants]]. | These fixed values are used within the model for the day scenario. A night scenario is also available, see [[#Variants|Variants]]. | ||

| − | + | {| border="1" align="center" cellpadding="5" cellspacing="0" | |

| − | + | |- bgcolor=#c7c7c7 | |

| − | + | ! Symbol !! Value !! Unit !! Description | |

| − | \dot{Q}_{airload} | + | |- |

| − | \dot{m}_{ref,const} | + | | align=center | <math>\dot{Q}_{airload}</math> || align=right | 3000.00 || <math>\frac{J}{s}</math> || Disturbance, heat transfer from outside the display case |

| − | M_{goods} | + | |- |

| − | C_{p,goods} | + | | align=center | <math>\dot{m}_{ref,const}</math> || align=right | 0.20 || <math>\frac{kg}{s}</math> || Disturbance, constant mass flow of refrigerant |

| − | UA_{goods-air} | + | from unmodeled entities |

| − | M_{wall} | + | |- |

| − | C_{p,wall} | + | | align=center | <math>M_{goods}</math> || align=right | 200.00 || <math>kg</math> || Mass of goods |

| − | UA_{air-wall} | + | |- |

| − | M_{air} | + | | align=center | <math>C_{p,goods}</math> || align=right | 1000.00 || <math>\frac{J}{kg \cdot K}</math> || Heat capacity of goods |

| − | C_{p,air} | + | |- |

| − | UA_{wall-ref,max} | + | | align=center | <math> |

| − | \tau_{fill} | + | UA_{goods-air} </math> || align=right | 300.00 || <math>\frac{J}{s \cdot K}</math> || Heat transfer coefficient between goods |

| − | T_{SH} | + | and air |

| − | M_{ref,max} | + | |- |

| − | V_{suc} | + | | align=center | <math>M_{wall} </math> || align=right | 260.00 || <math>kg</math> || Mass of evaporator wall |

| − | V_{sl} | + | |- |

| − | \eta_{vol} | + | | align=center | <math>C_{p,wall} </math> || align=right | 385.00 || <math>\frac{J}{kg \cdot K}</math> || Heat capacity of evaporator wall |

| + | |- | ||

| + | | align=center | <math>UA_{air-wall}</math> || align=right | 500.00 || <math>\frac{J}{s \cdot K}</math> || Heat transfer coefficient between air and | ||

| + | wall | ||

| + | |- | ||

| + | | align=center | <math>M_{air}</math> || align=right | 50.00 || <math>kg</math> || Mass of air in display case | ||

| + | |- | ||

| + | | align=center | <math>C_{p,air}</math> || align=right | 1000.00 || <math>\frac{J}{kg \cdot K}</math> || Heat capacity of air | ||

| + | |- | ||

| + | | align=center | <math>UA_{wall-ref,max}</math> || align=right | 4000.00 || <math>\frac{J}{s \cdot K}</math> || Maximum heat transfer coefficient between | ||

| + | refrigerant and evaporator wall | ||

| + | |- | ||

| + | | align=center | <math>\tau_{fill}</math> || align=right | 40.00 || <math>s</math> || Parameter describing the filling time of the | ||

| + | evaporator under opened valve | ||

| + | |- | ||

| + | | align=center | <math>T_{SH}</math> || align=right | 10.00 || <math>K</math> || Superheat in the suction manifold | ||

| + | |- | ||

| + | | align=center | <math>M_{ref,max}</math> || align=right | 1.00 || <math>kg</math> || Maximum mass of refrigerant in evaporator | ||

| + | |- | ||

| + | | align=center | <math>V_{suc}</math> || align=right | 5.00 || <math>m^3</math> || Total volume of suction manifold | ||

| + | |- | ||

| + | | align=center | <math>V_{sl}</math> || align=right | 0.08 || <math>\frac{m^3}{s}</math> || Total displacement volume | ||

| + | |- | ||

| + | | align=center | <math>\eta_{vol}</math> || align=right | 0.81 || <math>-</math> || Volumetric efficiency | ||

| + | |} | ||

| + | == Reference Solutions == | ||

| − | \ | + | For the relaxed problem (we only demand <math>u_i(t) \in [0,1]</math> instead of <math>u_i(t) \in \{0,1\}</math>) the optimal solution is 12072.45. |

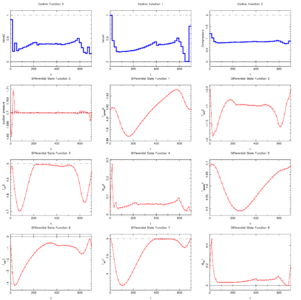

| − | </math> | + | The illustrated solution with integer controls has a (suboptimal) objective function value of 12252.81. |

| − | = | + | <gallery caption="Reference solution plots" widths="350px" heights="300px" perrow="2"> |

| + | Image:FridgeControlsRelaxed.png| Optimal relaxed control. | ||

| + | Image:FridgeControls.png| Optimal integer control. | ||

| + | </gallery> | ||

| − | |||

| − | |||

== Source Code == | == Source Code == | ||

| − | + | Model descriptions are available in | |

| − | + | * [[:Category:Muscod | Muscod code]] at [[Supermarket refrigeration system (Muscod)]] | |

| − | + | * [[:Category:JModelica | JModelica code]] at [[Supermarket refrigeration system (JModelica)]] | |

| − | + | ||

| − | + | ||

| − | + | == Variants == | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | // | + | Since the compressors are parallel connected one can introduce a single control <math> u_2 \in \{0,1,2\}</math> instead of two equivalent controls. The same holds for scenarions with <math> n </math> parallel connected compressors. |

| − | + | ||

| − | + | ||

| − | / | + | In the paper <bib id="Larsen2007" /> mentioned above, the problem was stated slightly different: |

| − | + | ||

| − | + | ||

| − | + | * The temperature constraints weren't hard bounds but there was a penalization term added to the objective function to minimize the violation of these constraints. | |

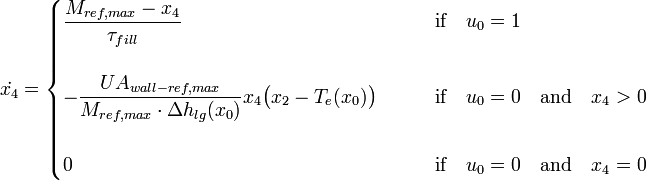

| − | + | * The differential equation for the mass of the refrigerant had another switch, if the valve (e.g. <math>u_0</math>) is closed. It was formulated this way: | |

| − | + | <math> | |

| − | + | \dot{x_4} = \begin{cases} | |

| − | + | ||

| − | + | \dfrac{M_{ref,max} - x_4}{\tau_{fill}} & \qquad \text{if} \quad u_0 = 1 \\ \\ | |

| − | + | - \dfrac{UA_{wall-ref,max}}{M_{ref,max} \cdot \Delta h_{lg}(x_0)} x_4 \big( x_2 - T_e(x_0) \big) & \qquad \text{if} \quad u_0 = 0 \quad \text{and}\quad x_4 > 0 \\ \\ | |

| − | + | 0 & \qquad \text{if} \quad u_0 = 0 \quad \text{and} \quad x_4 = 0 | |

| − | + | ||

| − | + | ||

| − | + | \end{cases} | |

| + | </math> | ||

| − | + | This additional switch is redundant because the mass itself is a factor on the right hand side and so the complete right hand side is 0 if <math>x_4 = 0</math>. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

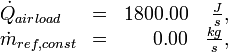

* A night scenario with two different parameters was given. At night the following parameters change their value: | * A night scenario with two different parameters was given. At night the following parameters change their value: | ||

<math> | <math> | ||

| Line 249: | Line 213: | ||

Additionally the constraint on the suction pressure <math>x_0(t)</math> is softened to <math>x_0(t) \leq 1.9</math>. | Additionally the constraint on the suction pressure <math>x_0(t)</math> is softened to <math>x_0(t) \leq 1.9</math>. | ||

| − | |||

* No periodicity was required but the solution on a fixed time horizon 4 hours - 2 in day scenario and 2 in night scenario - with <math>t_f = 14400</math> was asked. | * No periodicity was required but the solution on a fixed time horizon 4 hours - 2 in day scenario and 2 in night scenario - with <math>t_f = 14400</math> was asked. | ||

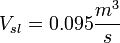

* The number of compressors and display cases is not fixed. Larsen also proposed the problem with 3 compressors and 3 display cases. This leads to a change in the compressor rack's preformance to <math>V_{sl} = 0.095 \frac{m^3}{s}</math>. Unfortunately this constant is only given for these two cases although Larsen proposed scenarios with more compressors and display cases. | * The number of compressors and display cases is not fixed. Larsen also proposed the problem with 3 compressors and 3 display cases. This leads to a change in the compressor rack's preformance to <math>V_{sl} = 0.095 \frac{m^3}{s}</math>. Unfortunately this constant is only given for these two cases although Larsen proposed scenarios with more compressors and display cases. | ||

== References == | == References == | ||

| − | < | + | <biblist /> |

<!--List of all categories this page is part of. List characterization of solution behavior, model properties, ore presence of implementation details (e.g., AMPL for AMPL model) here --> | <!--List of all categories this page is part of. List characterization of solution behavior, model properties, ore presence of implementation details (e.g., AMPL for AMPL model) here --> | ||

| Line 260: | Line 223: | ||

[[Category:ODE model]] | [[Category:ODE model]] | ||

[[Category:Chattering]] | [[Category:Chattering]] | ||

| + | [[Category:Periodic]] | ||

| + | [[Category:Minimum energy]] | ||

Latest revision as of 10:33, 27 July 2016

| Supermarket refrigeration system | |

|---|---|

| State dimension: | 1 |

| Differential states: | 9 |

| Discrete control functions: | 3 |

| Path constraints: | 7 |

| Interior point equalities: | 9 |

The supermarket refrigeration system problem is based on a model describing a refrigeration system with 2 parallel connected compressors (called a compressor rack) which only can be controlled stepwise (each single compressor can be turned on or off) and 2 open refrigerated display cases containing goods needed to be refrigerated. Each display case is connected to the refrigeration circuit through an expansion valve which also can only be closed or opened. This valve controls the flow of refrigerant into the evaporator, where it absorbs heat from the surrounding air. The refrigerated air then creates the well-known air-curtain at the front of the display case.

The air temperatures surrounding the goods in each display case are modeled by one differential state each. These states have to be bounded, so that the goods are properly refrigerated.

The model was published by Larsen et. al. in 2007 [Larsen2007]Author: Larsen, L.F.S.; Izadi-Zamanabadi, R.; Wisniewski, R.; Sonntag, C.

Institution: Technical report for the HYCON NoE.

Note: http://www.bci.tu-dortmund.de/ast/hycon4b/index.php

Title: Supermarket Refrigeration Systems -- A benchmark for the optimal control of hybrid systems

Year: 2007 . The main goal is to control the refirgeration system energy-optimal. The problem was set up as a benchmark problem for MIOCPs.

. The main goal is to control the refirgeration system energy-optimal. The problem was set up as a benchmark problem for MIOCPs.

The mathematical equations form an ODE model. The initial values of the differential states are not fixed but periodicity of the whole process is required.

The optimal integer control function shows chattering behavior, making the supermarket refrigeration system problem a candidate for benchmarking of algorithms.

Contents

[hide]Mathematical formulation

For ![t \in [t_0, t_f]](https://mintoc.de/images/math/5/5/8/55823791d9100bcb5461801aff4f6edd.png) almost everywhere the mixed-integer optimal control problem is given by

almost everywhere the mixed-integer optimal control problem is given by

![\begin{array}{llcl}

\displaystyle

\mbox{s.t.} &

\dot{x_0} &=& \dfrac{1}{V_{suc} \cdot \frac{d\rho_{suc}}{dP_{suc}}(x_0)} \cdot \bigg[

\left(\dfrac{UA_{wall-ref, max}}{M_{ref, max} \cdot

\Delta h_{lg}(x_0)}\right) \Big( x_4 \big( x_2 - T_e(x_0) \big)\\

& && + \, x_8 \big( x_6 - T_e(x_0) \big) \Big) + \, M_{ref,const} - \eta_{vol} \cdot V_{sl} \cdot 0.5 \, u_2 \rho_{suc}(x_0)

\bigg] \\

&\dot{x_1} &=& - \dfrac{

UA_{goods-air} \left( x_1 - x_3 \right)

}{

M_{goods} \cdot C_{p,goods}

} \\

&\dot{x_2} &=& \dfrac{

UA_{air-wall} \left( x_3-x_2 \right)

- \dfrac{UA_{wall-ref,max}}{M_{ref,max}}

\, x_4 \big( x_2 - T_e(x_0) \big)

}{

M_{wall} \cdot C_{p,wall}

} \\ [2.5ex]

&\dot{x_3} &=& \dfrac{

UA_{goods-air} \left( x_1-x_3 \right) + \dot{Q}_{airload}

- UA_{air-wall} \, (x_3-x_2)

}{

M_{air} \cdot C_{p,air}

} \\ [2.5ex]

&\dot{x_4} &=& \left(\dfrac{M_{ref,max} - x_4}{\tau_{fill}} \right) u_0

- \left( \dfrac{UA_{wall-ref,max}}{M_{ref,max} \cdot \Delta h_{lg}(x_0)} \,

x_4 \big( x_2 - T_e(x_0) \big) \right) (1-u_0)

\\ \\

&\dot{x_5} &=& - \dfrac{

UA_{goods-air} \left( x_5 - x_7 \right)

}{

M_{goods} \cdot C_{p,goods}

} \\

&\dot{x_6} &=& \dfrac{

UA_{air-wall} \left( x_7-x_6 \right)

- \dfrac{UA_{wall-ref,max}}{M_{ref,max}}

\, x_8 \big( x_6 - T_e(x_0) \big)

}{

M_{wall} \cdot C_{p,wall}

} \\ [2.5ex]

&\dot{x_7} &=& \dfrac{

UA_{goods-air} \left( x_5-x_7 \right) + \dot{Q}_{airload}

- UA_{air-wall} \, (x_7-x_6)

}{

M_{air} \cdot C_{p,air}

} \\ [2.5ex]

&\dot{x_8} &=& \left(\dfrac{M_{ref,max} - x_8}{\tau_{fill}} \right) u_1

- \left( \dfrac{UA_{wall-ref,max}}{M_{ref,max} \cdot \Delta h_{lg}(x_0)} \,

x_8 \big( x_6 - T_e(x_0) \big) \right) (1-u_1)

\\ [4ex]

& x_3 &\geq& 2.0 \quad \forall t \in [t_0, t_f],\\

& x_3 &\leq& 5.0 \quad \forall t \in [t_0, t_f],\\

& x_7 &\geq& 2.0 \quad \forall t \in [t_0, t_f],\\

& x_7 &\leq& 5.0 \quad \forall t \in [t_0, t_f],\\

& x_0 &\leq& 1.7 \quad \forall t \in [t_0, t_f], \\

& x_i(t_0) &=& free \quad \forall i \in \{0,\dots, 8\}, \\

& x_i(t_f) &=& x_i(t_0) \quad \forall i \in \{0,\dots, 8\}, \\

& u_i(t) &\in& \{0, 1\} \quad \forall i \in \{0,\dots, 2\}, \\

& t_f &\in& [ 650, 750 ].

\end{array}](https://mintoc.de/images/math/7/8/1/781b7d39eeeecfc6ad17b0904e043b97.png)

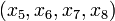

Here the differential state  describes the suction pressure in the suction manifold (in bar). The next three states model temperatures in the first display case (in °C).

describes the suction pressure in the suction manifold (in bar). The next three states model temperatures in the first display case (in °C).  is the goods' temperature,

is the goods' temperature,  the one of the evaporator wall and

the one of the evaporator wall and  the air temperature surrounding the goods.

the air temperature surrounding the goods.  then models the mass of the liquefied refrigerant in the evaporator (in kg).

then models the mass of the liquefied refrigerant in the evaporator (in kg).

describe the corresponding states in the second display case.

describe the corresponding states in the second display case.

describes the inlet valve of the first display case,

describes the inlet valve of the first display case,  respectively the valve of the second display case.

respectively the valve of the second display case.

denote the activity of a single compressor.

denote the activity of a single compressor.

The following polynomial functions are used in the model description originating from interpolations:

Parameters

These fixed values are used within the model for the day scenario. A night scenario is also available, see Variants.

| Symbol | Value | Unit | Description |

|---|---|---|---|

|

3000.00 |  |

Disturbance, heat transfer from outside the display case |

|

0.20 |  |

Disturbance, constant mass flow of refrigerant

from unmodeled entities |

|

200.00 |  |

Mass of goods |

|

1000.00 |  |

Heat capacity of goods |

|

300.00 |  |

Heat transfer coefficient between goods

and air |

|

260.00 |  |

Mass of evaporator wall |

|

385.00 |  |

Heat capacity of evaporator wall |

|

500.00 |  |

Heat transfer coefficient between air and

wall |

|

50.00 |  |

Mass of air in display case |

|

1000.00 |  |

Heat capacity of air |

|

4000.00 |  |

Maximum heat transfer coefficient between

refrigerant and evaporator wall |

|

40.00 |  |

Parameter describing the filling time of the

evaporator under opened valve |

|

10.00 |  |

Superheat in the suction manifold |

|

1.00 |  |

Maximum mass of refrigerant in evaporator |

|

5.00 |  |

Total volume of suction manifold |

|

0.08 |  |

Total displacement volume |

|

0.81 |  |

Volumetric efficiency |

Reference Solutions

For the relaxed problem (we only demand ![u_i(t) \in [0,1]](https://mintoc.de/images/math/3/8/4/384c39a979a193e236c98a273eacc57a.png) instead of

instead of  ) the optimal solution is 12072.45.

The illustrated solution with integer controls has a (suboptimal) objective function value of 12252.81.

) the optimal solution is 12072.45.

The illustrated solution with integer controls has a (suboptimal) objective function value of 12252.81.

- Reference solution plots

Source Code

Model descriptions are available in

- Muscod code at Supermarket refrigeration system (Muscod)

- JModelica code at Supermarket refrigeration system (JModelica)

Variants

Since the compressors are parallel connected one can introduce a single control  instead of two equivalent controls. The same holds for scenarions with

instead of two equivalent controls. The same holds for scenarions with  parallel connected compressors.

parallel connected compressors.

In the paper [Larsen2007]Author: Larsen, L.F.S.; Izadi-Zamanabadi, R.; Wisniewski, R.; Sonntag, C.

Institution: Technical report for the HYCON NoE.

Note: http://www.bci.tu-dortmund.de/ast/hycon4b/index.php

Title: Supermarket Refrigeration Systems -- A benchmark for the optimal control of hybrid systems

Year: 2007 mentioned above, the problem was stated slightly different:

mentioned above, the problem was stated slightly different:

- The temperature constraints weren't hard bounds but there was a penalization term added to the objective function to minimize the violation of these constraints.

- The differential equation for the mass of the refrigerant had another switch, if the valve (e.g.

) is closed. It was formulated this way:

) is closed. It was formulated this way:

This additional switch is redundant because the mass itself is a factor on the right hand side and so the complete right hand side is 0 if  .

.

- A night scenario with two different parameters was given. At night the following parameters change their value:

Additionally the constraint on the suction pressure  is softened to

is softened to  .

.

- No periodicity was required but the solution on a fixed time horizon 4 hours - 2 in day scenario and 2 in night scenario - with

was asked.

was asked. - The number of compressors and display cases is not fixed. Larsen also proposed the problem with 3 compressors and 3 display cases. This leads to a change in the compressor rack's preformance to

. Unfortunately this constant is only given for these two cases although Larsen proposed scenarios with more compressors and display cases.

. Unfortunately this constant is only given for these two cases although Larsen proposed scenarios with more compressors and display cases.

References

There were no citations found in the article.